Description

For privacy reasons YouTube needs your permission to be loaded. For more details, please see our

Privacy Policy.

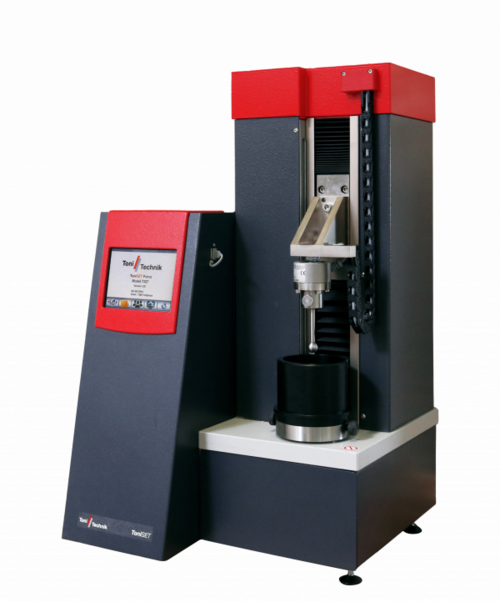

The ToniSET Classic is designed as a three-axle measuring system, that comes with 8 measuring stations. The three axes are driven by gear motors while optical switches are monitoring the respective final positions.The test stations are arranged in two rows inside a basin that allows testing under water.

The Vicat moulds are installed in the basin by means of corresponding base plates.

The penetration depths of the needle are exactly measured by an incremental, contact-free measuring system. By an easy exchange of the drop rod the different drop weights can be realized.

The ToniSET Classic is equipped with an automatic cleaning system for the Vicat needle.

A serial interface type RS232 enables the connection of the PC system that is needed to operate the instrument.

Operating Principle

The ToniSET CLASSIC is operated by an external PC system (WINDOWS®) using the software VicatDB. Tests are prepared, controlled and evaluated by this software. After the onetime definition of the test parameters tests can be started directly after the input of an identification and the preparation of the specimen. Subsequently the instrument performs the test fully automatic and stores the measured values in a data base. The needle is cleaned by a water jet after each penetration.

During the test procedure all measured values as well as the actual setting progress can be read out at any time. A selectable quick measurement mode allows shortest penetration sequences if required.

After the end of the test the evaluation can be done either automatically by the software or manually by the operator.