Testing Machines and Instruments for Refractory

Refractory

Non-metallic ceramic materials and composites with a softening point above 1,500 °C are defined as refractory materials.

Refractory materials are divided into shaped (e.g. bricks, blocks, slabs) and unshaped (e.g. cement, mortar, concrete) materials and are mainly used in high-temperature industrial applications.

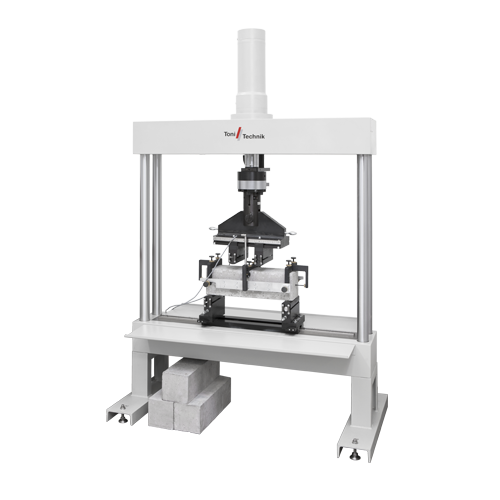

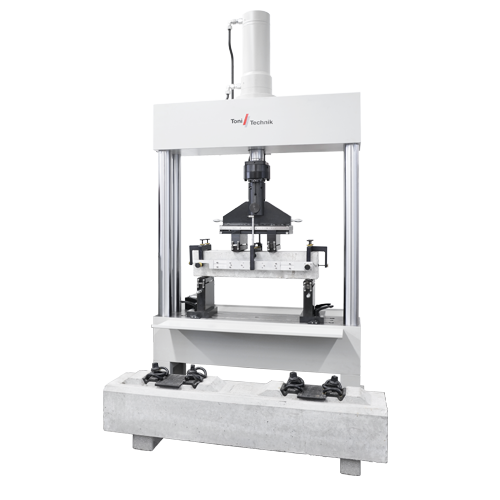

Testing Machines

Testing Instruments

Why choose us?

We fabricate and assemble our machines and instruments ourselves in Germany based on individual customer orders and specifications. A competent and experienced team of mechanical and electronic technicians guarantees the high quality level our customers expect.

Toni Technik has been in the market for more than 140 years. We have improved constantly the quality of our products to fulfill the need of our customers. What’s more, since 2002 we are a member of the ZwickRoell/Roell Group and we have developed a range of instruments for testing cement and mortar.

Our customers can rely on receiving exclusively quality “Made in Germany” by Toni Technik. This is confirmed and sealed by our quality management system, which is certified according to ISO 9001.

Our customers are the core of Toni Technik. They represent the importance of our business. We work strongly every day in order to improve our customer satisfaction together with the quality of our products.