Testing Machines and Instruments for Adhesives

Adhesives Chemical Industry

In addition to the setting time, adhesives are also tested for their adhesive tensile and shear strength in classical building material testing.

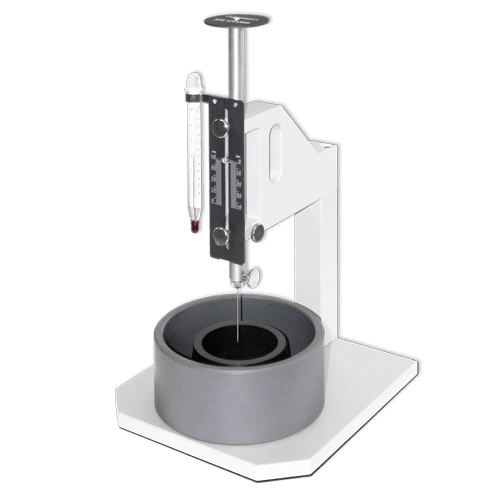

The setting times are often tested with Vicat devices according to EN 196-3, with a needle or according to DIN EN 13279-2 with a plunge cone. The challenge here is the strong adhesion of the material to the indenter. Effective, automatic cleaning is therefore of crucial importance for test performance.

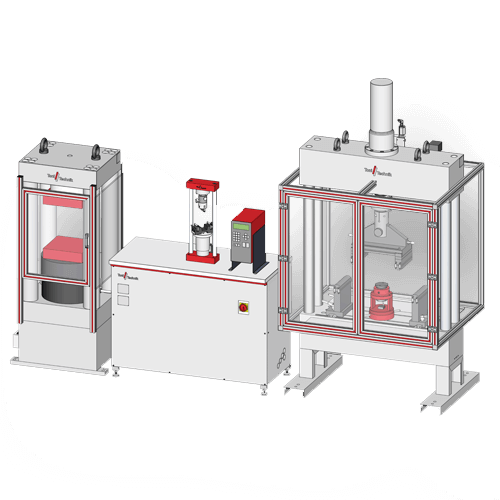

The tensile adhesion test is usually performed with mobile hand-held equipment, usually up to 20 kN. If the test volume is high, testing machines with large frame dimensions are also used in order to be able to position large-format specimen pads individually under the force axis.

Adhesive shear tests are carried out according to various standards with special fixtures in our machines.