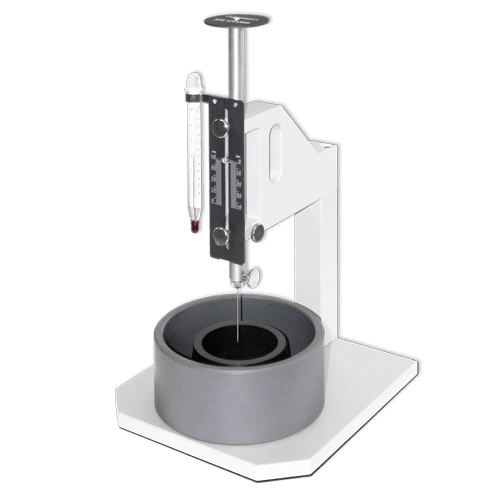

Testing Machines and Instruments for Mortar

Mortar

Mortar is a building material consisting mainly of a binder (e.g. lime or cement), aggregates with a maximum particle size of 4 mm, and water, which hardens by a chemical reaction of the binders.

The mortar is primarily used for durable and weatherproof bonding of bricks and for plastering walls and ceilings. It is produced either in the factory or directly on the construction site.

In practice, there are countless mortar products with sometimes very different mechanical and physical properties. Masonry mortar, for example, must above all be compression-resistant.

The physical properties are defined in the international testing standards for which Toni Technik’s testing machines and equipment are designed.