The protection and repair of existing buildings are becoming increasingly important. In addition to weather protection and durability, building reinforcement is gaining more focus in new developments. One system available for this purpose is fiber-reinforced shotcrete.

This composite system not only provides long-term protection to the existing building structure but can also increase its load-bearing capacity. Various test methods already exist for testing fiber-reinforced concretes, which aim to determine the residual load-bearing capacity after exceeding the maximum strength.

These test methods require advanced testing technology as they are deformation-controlled and go beyond Fmax (maximum strength). It is not uncommon for a significant portion of the energy stored in the testing frame to be rapidly dissipated from the system in milliseconds to maintain the required deformation speed at the breaking point.

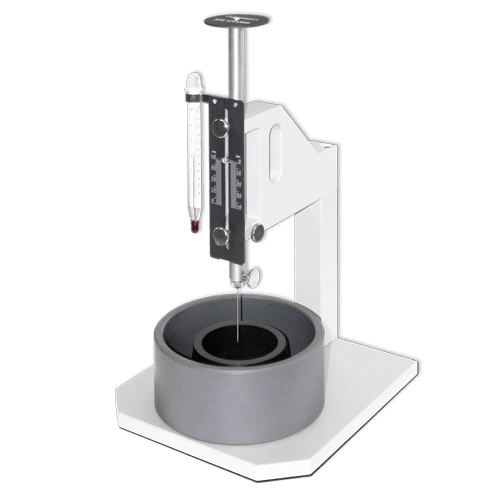

For testing structural coatings, there is a relatively new test procedure according to EN 14891. In this test method, a slim prism measuring 40 x 12(15) x 160 mm is manufactured preferably from the carrier material, which contains a predetermined breaking point in the middle.

The coating is then applied to one side following the manufacturer’s instructions and stored if necessary. The prism is subsequently broken in a specialized device on the uncoated side at the predetermined breaking point. This produces a highly defined tensile test specimen and allows for reproducible testing of the coatings’ adhesion, elasticity, and tensile strength.

To accomplish this, the small testing machine requires pre-defined positive-locking adapters to initiate the load without inducing stress.