Testing Machines and Instruments for Pharmaceuticals

Pharmaceuticals

Advanced Quality Control in Micronization of Powders

Specific Surface Area Measurements acc. to Blaine

Basics

Blaine fineness based on air permeability measurement, provides information on the specific surface area (SSA) of a powder sample, the surface area per unit mass.

Finer particle sizes have higher specific surface area, which means more area per unit mass, so the Blaine value gives a precise indication about particle size range to decide on further micronization.

Importance

Mandatory as per Pharmacopeial requirements, SSA plays an important role in drug formulation like tableting, drug shelf-life and bioavailability. Also, the blending between APIs and Excipients is critical.

SSA also affects the solubility and dissolution pattern of the tablet drug and can influence the surface activity and adsorption volume of the powder.

Application areas

- R&D

- Process control for optimization

- Quality assurance

- Pharmaceuticals products (Active pharmaceutical ingredients (APIs)/Excipients/Chemicals etc.)

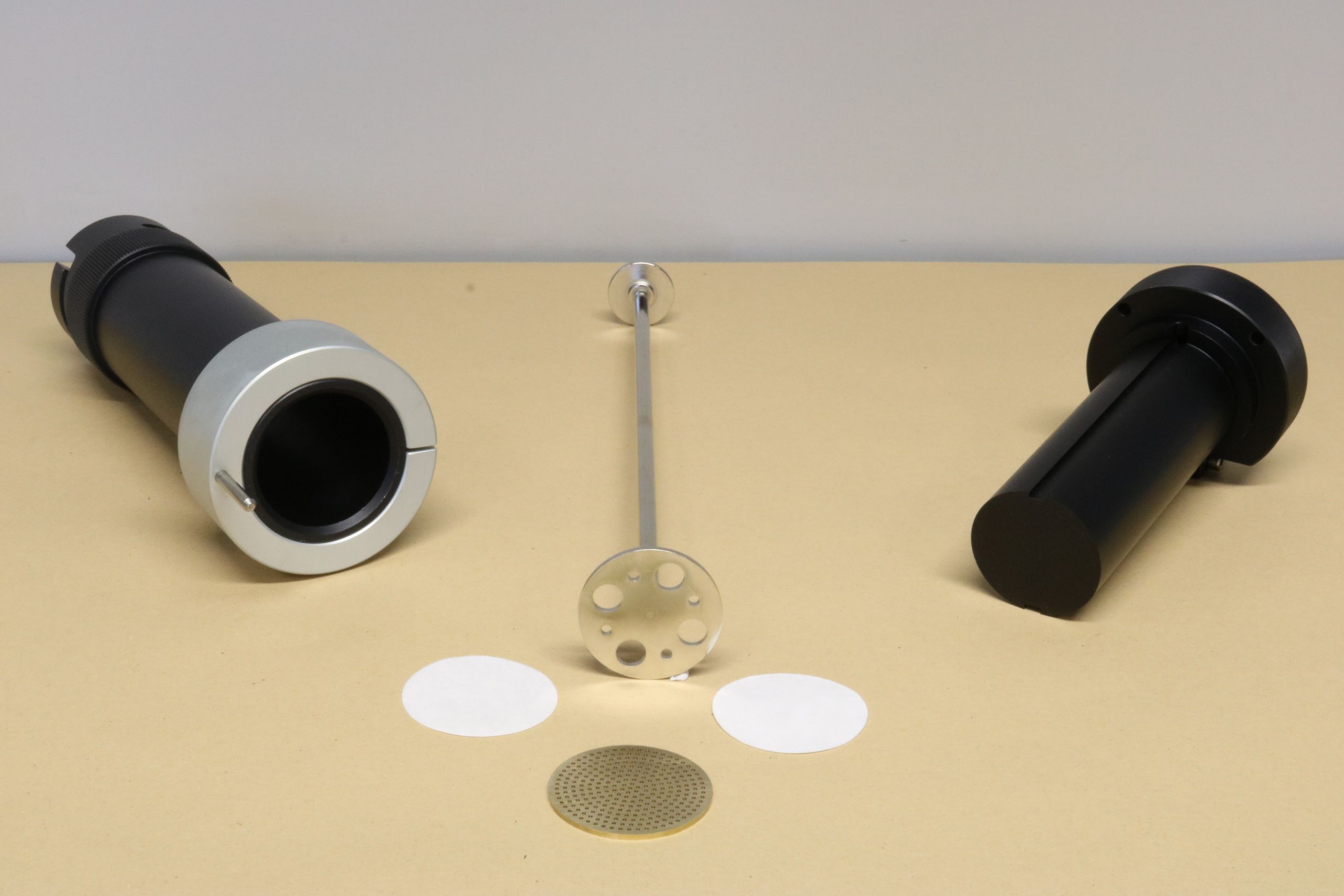

Methodology

Air permeability measurements record the time taken by a certain volume of air to pass through a compacted powder bed of defined weight and porosity.

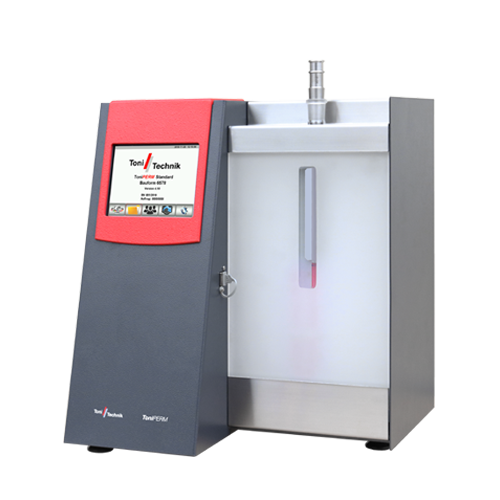

ToniPERM Standard

ToniPERM II

Unique features

- Fully automated device

- Data integrity and traceability

- Interface: ethernet, serial (RS232) and USB

- Plug & play instrument (no PC needed)

Your benefits

- Cost effective and quick solution for a precise indication of particle size

- Customization possibilities

Why choose us?

We fabricate and assemble our machines and instruments ourselves in Germany based on individual customer orders and specifications. A competent and experienced team of mechanical and electronic technicians guarantees the high quality level our customers expect.

Toni Technik has been in the market for more than 140 years. We have improved constantly the quality of our products to fulfill the need of our customers. What’s more, since 2002 we are a member of the ZwickRoell Group and we have developed a range of instruments for testing cement and mortar.

Our customers can rely on receiving exclusively quality “Made in Germany” by Toni Technik. This is confirmed and sealed by our quality management system, which is certified according to ISO 9001.

Our customers are the core of Toni Technik. They represent the importance of our business. We work strongly every day in order to improve our customer satisfaction together with the quality of our products.