Similar as with concrete, cement also serves as a binding agent for the production of various types of mortar (gypsum, lime and cement mortar), including ready-mixed or dry mortar on a mineral or partially mineral basis.

Mortar is a building material consisting mainly of a binding agent (e.g. lime or cement), aggregates with a maximum grain size of 4 mm and water, which hardens by a chemical reaction of the binding agents.

The mortar is primarily used for the durable and weatherproof bonding of bricks and for plastering walls and ceilings. It is produced either in the factory or directly at the construction site.

Mortar is almost exactly the same as concrete, except that it contains only aggregates up to a maximum grain size of 4 mm, i.e. no gravel. Both materials contain cement. At least this applies to the classic cement mortar. However, there are also types of mortar that contain other binding agents instead of cement, e.g. lime – in this case we speak of lime mortar. Furthermore, there is also gypsum, clay, synthetic resin or the mixed form of lime-cement mortar.

Depending on the application, a distinction is made, for example, between masonry mortar, tile mortar or tile adhesive, adhesive mortar for composite thermal insulation systems and screed mortar, as well as filler and levelling compounds, which also belong to the group of mortars. The plaster product group also includes mortars: Plaster mortars with which ceilings or walls are coated.

In practice, there are countless mortar products with sometimes very different mechanical and physical properties. Masonry mortars, for example, must above all be pressure-resistant.

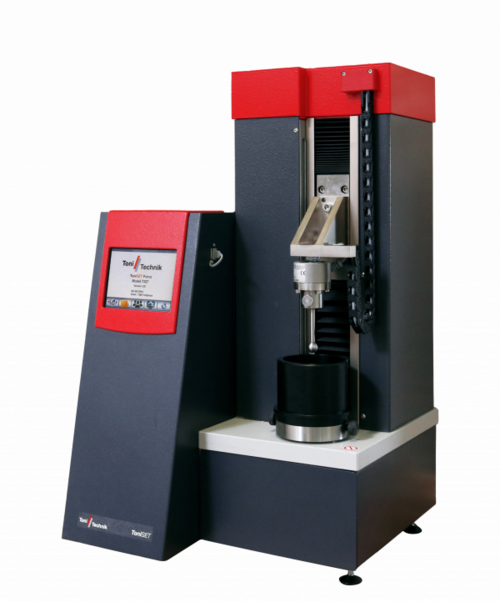

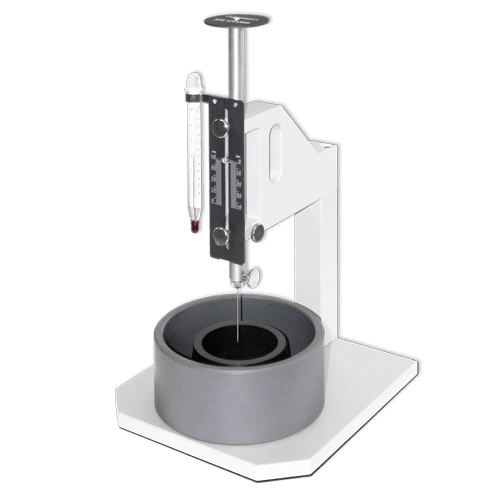

The physical properties are defined in the international testing standards to which Toni Technik’s testing machines and equipment are designed for.