Description

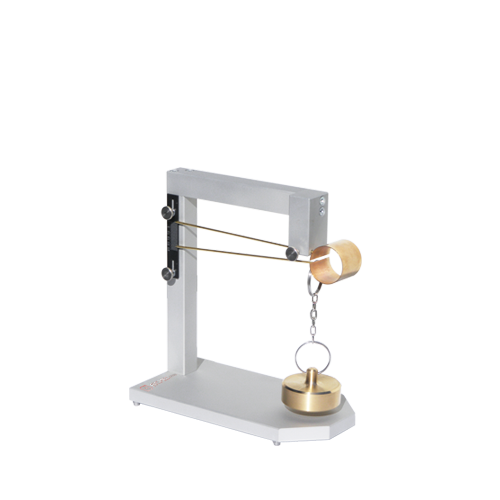

Operating Principle

The moulds in the support frames are surrounded by saturated humid air. The humidity is generated by evaporating water from the bottom reservoir. A fan is integrated for equal distribution of temperature and humidity. As the container has no temperature controller, the storage temperature depends on the ambient temperature. Depending on the thermal process energy from curing, the temperature inside the container may be 1.5 °C higher than the ambient temperature. The adjustable vents in the container lid allow warm air to escape. Separation of storage container and working table allows the operator to work on the table without jolting the stored specimens.

Design

The sturdy working table features a robust tubular steel substructure and a sleek stainless steel tabletop, combining durability and elegance. Below the tabletop, there is a separate storage container made of high-quality stainless steel, offering convenient storage space. The table also boasts adjustable legs, allowing you to customize the height according to your preference.

The lower part of the table is intelligently designed to serve as a water reservoir, providing a reliable source for various purposes. The support structures above are skillfully guided in drawer rails, ensuring smooth and effortless movement. This setup allows for easy access to the reservoir while maintaining stability.

To enhance efficiency, the table is equipped with three frames on each side, capable of accommodating two or four molds each. This thoughtful design maximizes workspace utilization and facilitates organized working conditions.

In order to regulate the thermal energy generated during the curing process, adjustable openings are strategically placed in the front part of the container lid. This ventilation system effectively dissipates excess heat, contributing to a controlled environment. The two hinged doors located at the front of the container feature sturdy handles, providing secure closure and easy access to the contents within. Furthermore, a thermo-hygrometer is thoughtfully integrated into one of the doors, enabling constant monitoring of temperature and humidity levels.