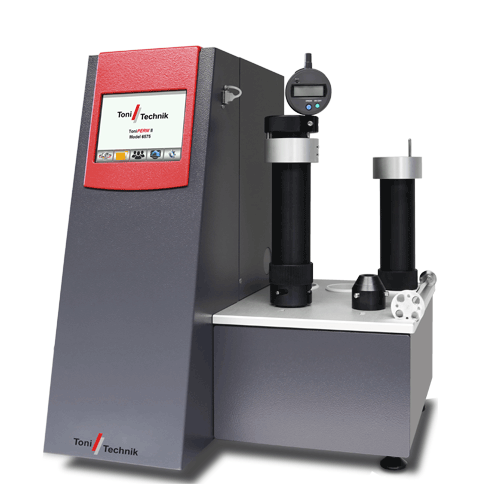

The air permeability tester ToniPERM II is designed for the determination of the specific surface of powders, especially suitable for the permanent control of manufacturing characteristics in the daily laboratory work. This measuring procedure serves as practice oriented alternative for the standard procedures according to EN 196 as well as ASTM C 204.

Key benefits for the user:

- Simple operation with reproducible results

- Intuitive operation with touchscreen

- Automatic volume correction

- Automatic quadruple test of a double sample with a single operating effort

- Robust, low-maintenance design*

- Easy data export via LAN interface ** or USB stick

* Ask about our extended warranty terms

** ToniLINK software required