- Increased efficiency through parallel automatic determination of the setting behavior in conformity with standards

- Robust low-maintenance execution with automatic cleaning of the penetrating needle

- Fast tesing mode for rapid setting building materials

- Easy data export via USB stick

- Simple conversion to other product standards e.g. cement, mortar in less than one minute

Similar as with concrete, cement also serves as a binding agent for the production of various types of mortar (gypsum, lime and cement mortar), including ready-mixed or dry mortar on a mineral or partially mineral basis.

Mortar is a building material consisting mainly of a binding agent (e.g. lime or cement), aggregates with a maximum grain size of 4 mm and water, which hardens by a chemical reaction of the binding agents.

The mortar is primarily used for the durable and weatherproof bonding of bricks and for plastering walls and ceilings. It is produced either in the factory or directly at the construction site.

Mortar is almost exactly the same as concrete, except that it contains only aggregates up to a maximum grain size of 4 mm, i.e. no gravel. Both materials contain cement. At least this applies to the classic cement mortar. However, there are also types of mortar that contain other binding agents instead of cement, e.g. lime – in this case we speak of lime mortar. Furthermore, there is also gypsum, clay, synthetic resin or the mixed form of lime-cement mortar.

Depending on the application, a distinction is made, for example, between masonry mortar, tile mortar or tile adhesive, adhesive mortar for composite thermal insulation systems and screed mortar, as well as filler and levelling compounds, which also belong to the group of mortars. The plaster product group also includes mortars: Plaster mortars with which ceilings or walls are coated.

In practice, there are countless mortar products with sometimes very different mechanical and physical properties. Masonry mortars, for example, must above all be pressure-resistant.

The physical properties are defined in the international testing standards to which Toni Technik’s testing machines and equipment are designed for.

-

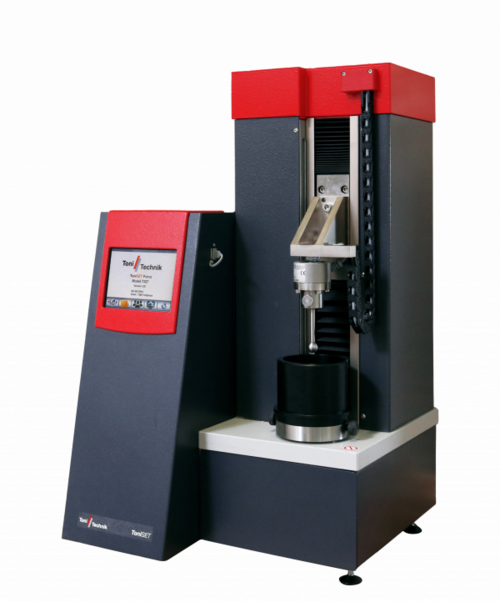

Automatic, computer-controlled Vicat needle instrument providing six measuring stations for the determination of the setting characteristics of binding materials, preferably of: Key benefits for the user:

-

Combined test plant for the standard-compliant testing of the compressive and flexural strength of cement and other binding materials, preferably for efficient routine tests of:

- Prisms 40 x 40 x 160 mm accord. to EN 196 / ISO 679

- Cubes 50 mm (2 inch) according to ASTM C109

- Cubes 70.7 mm according to BS 1881

Key benefits for the user:

- connection possibility for a third load frame, e.g. 3000 kN compression test frame for concrete testing

- possibility of machine control and test evaluation via a PC using testXpert software

- future-proof through retrofittable software modules

- possibility to connect to Laboratory Information and Management Systems (LIMS)

-

Test plant in compact design for efficient, standard-compliant compressive strength tests on cement and other binding materials, preferably on:

- delivery as a ready-to-use, space-saving compact unit: "Set up, connect, test".

- very easy programming and operation

- possibility to connect to Laboratory Information and Management Systems (LIMS)

- future-proof through retrofittable software options

- US-units selectable (lbs, psi, inch,…)

-

Compact, fully automatic test plant for standard-compliant flexural strength tests on cement and other binding materials, preferably on prisms 40 x 40 x 160 mm in accordance with EN 196 and ISO 679.

- Accuracy: Quality Class 1 / EN ISO 7500-1 / DIN 51220

- Sizes: 10 kN / 20 kN / 50 kN

-

The ToniFORCE is a fully automatic penetrometer for recording the setting behaviour of building materials like 3D printing concrete, cement, gypsum or mortar. The recorded data allow the determination of both the setting behaviour and the penetration resistance. A great milestone for Toni Technik: ToniFORCE Key benefits for the user:

- Accurate electronic measurement of the penetration depth

- Measurement of the penetration force (by precision force transducer based on strain gauges)

- Fully automatic test execution

- Stand-alone operation (no PC needed)

- Ambient temperature recording

- Test protocol in PDF format

- Connectivity to "Laboratory Information Management System" (LIMS) via integrated LAN interface

-

The jolting apparatus is designed for the standard-compliant compaction of cement mortar and other binding material in moulds and meets the entire requirements of the standards EN 196 part 1 and ISO 679. Key benefits for the user: ✓ Extremely sturdy, durable construction ✓ Solid, deformation-resistant table ✓ Clamping of the mold by quick clamping elements ✓ Comfortable one-button operation ✓ On demand delivery with foundation set or pre-casted concrete foundation ✓ Modification of the clamping device for moulds of other manufacturers is possible ✓ Sound protection hood for the reduction of the acoustic emission and for the protection of the user available

-

Load frame for efficient, standard-compliant flexural strength tests on mortar prisms, preferably on prisms 40x40x160 mm in accordance with EN 196 and ISO 679.

- Accuracy: Quality Class 1 / EN ISO 7500-1 / DIN 51220

- Sizes: 10 kN / 20 kN / 50 kN

-

Application Mortar mixer for the standard-compliant preparation of cement mortar and cement paste according to EN 196, ISO 679, DIN 1164, ASTM C 305, Ö-Norm B 3310 and further standards. Key benefits for the user:

- robust, durable housing

- wear-resistant, precise stirring tool

- possibility of adding granular and liquid aggregates during the mixing procedure

- integrated connection for dust exhaust

-

Standard-compliant operation according to EN 196-1, EN 196-3, EN 480-1, ASTM C 305, ASTM C 359, ASTM C 451, ISO 679 and according to own specifications. Automatic mixing of cement, mortar, gypsum and other materials including automated feed of sand and water, as well as torque measurement for the production of a defined viscosity. Advantages

- Our best Mixer with all features of ToniMIX Standard and ToniMIX Expert

- Determination and recording of viscosity behaviour of the mixture by means of torque measurement

- Equipped with an automatic sand feeding system

- Simply optimization of the mortar rheology by automatic water dosing to achieve a target viscosity value

- LED illuminated, visible mixing chamber

- Connection for a dust extraction device integrated

-

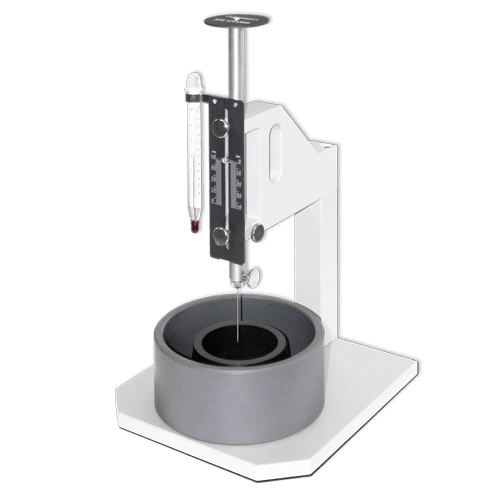

Application Manual Vicat needle device with a measuring point for determining the solidification behavior of binders, in particular:

- Cement according to EN 196, ASTM C 187 and ASTM C 191

- Mortar according to EN 480 and ASTM C 807

-

Application For the storage of specimens in tempered water. Advantages ✓ Compatible with the ToniSYSTEMLABORATORY ✓ Easy operation and handling ✓ High storage capacity by storage in six respectively seven levels ✓ Integrated thermostat with digital display for the actual value and the set value