ToniPERM II in Steel Industry

The pelletizing stage of steel making requires the fineness value, measured in cm2/g, that affects the balling process. A preferred Blaine value range before the balling process is between 1800 and 2000 cm2/g. An inappropriate Blaine value affects the homogeneity, quality and uniformness of the produced steel pellets. The fineness, therefore, needs to be checked before and after the dry grinding process.

Steel plants, iron ore plants, mining companies and research and development organizations measure the fineness to produce high quality pellets with a defined Cold Crushing Strength (CCS). Lesser fineness results in green pellets with weaker CCS due to the higher apparent porosity which makes the pellets highly brittle and generates more dust and fines during reduction. Higher fineness results in green pellets with higher CCS due to lesser apparent porosity which requires high induration temperature and high load requirement during the reduction process resulting in energy wastage. Therefore, optimum defined fineness measurement is important for the manufacturers.

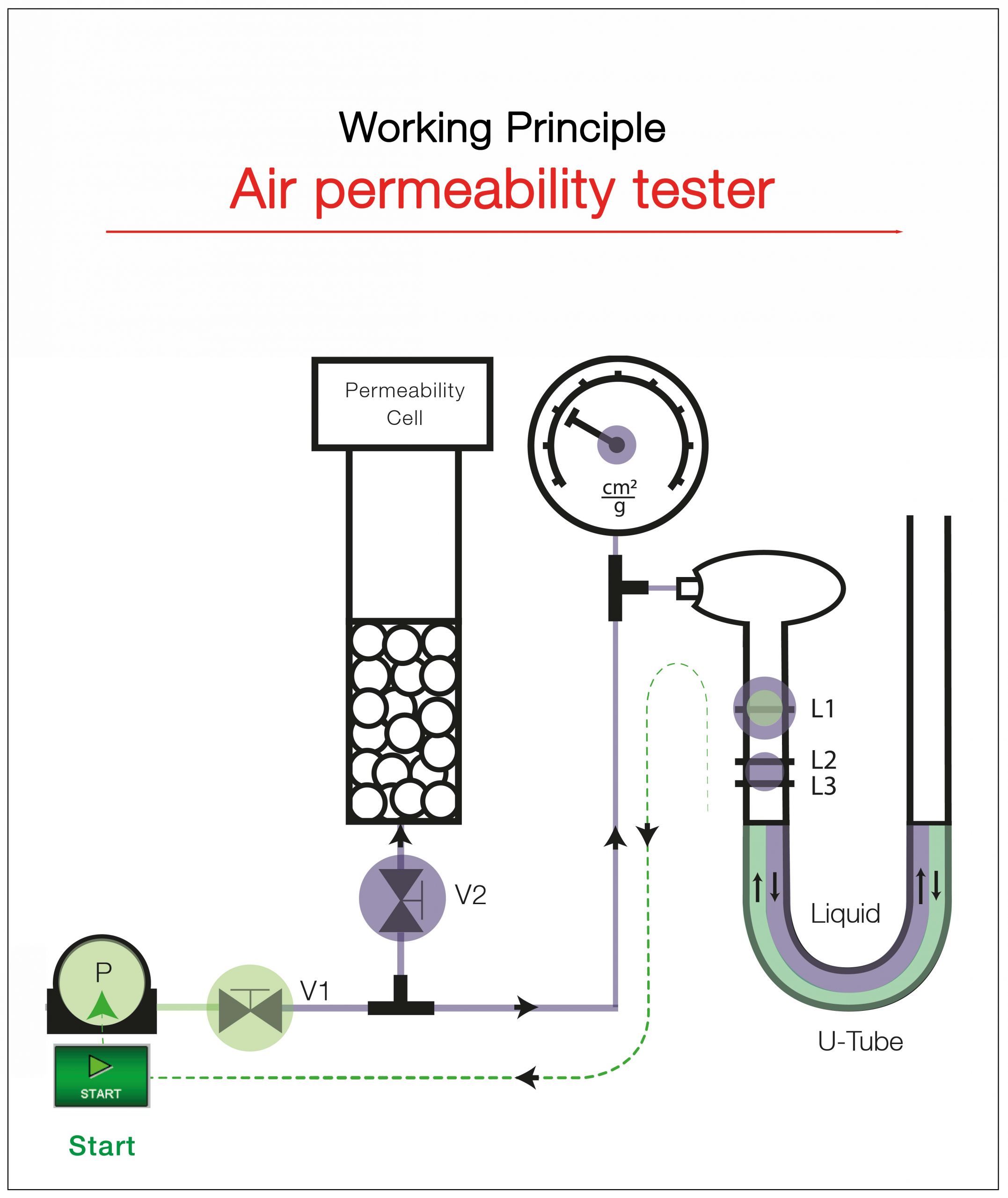

The air permeability tester ToniPERM II is designed for the determination of the specific surface area of powders, especially suitable for the permanent control of manufacturing characteristics in daily laboratory work. Originally developed to measure the fineness of cement and other cementitious materials, the ToniPERM II is now widely applied in the metal industry, among other applications.

|

Measuring range: 1.000 to 14.000 Blaine (cm2/g). |

|

High test frequency with two measuring cells. |

|

Measured data can be transferred to LIMS. |

Working principle: The fineness of a powder sample is determined by measuring the time, a defined amount of air needs to flow through the sample. Vacuum is generated by the help of a diaphragm pump and the time is measured by means of a U-tube manometer equipped with photoelectric sensors.