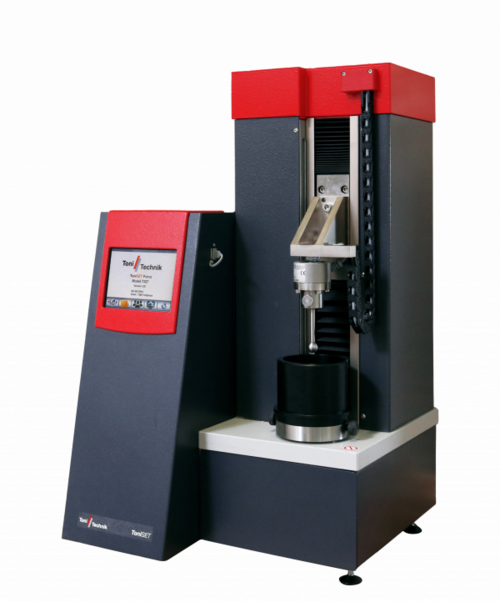

- Accurate electronic measurement of the penetration depth

- Measurement of the penetration force (by precision force transducer based on strain gauges)

- Fully automatic test execution

- Stand-alone operation (no PC needed)

- Ambient temperature recording

- Test protocol in PDF format

- Connectivity to "Laboratory Information Management System" (LIMS) via integrated LAN interface

-

The ToniFORCE is a fully automatic penetrometer for recording the setting behaviour of building materials like 3D printing concrete, cement, gypsum or mortar. The recorded data allow the determination of both the setting behaviour and the penetration resistance. A great milestone for Toni Technik: ToniFORCE Key benefits for the user:

-

Automatic Vicat needle instrument providing two or one measuring stations for the determination of the setting characteristics of binding materials, preferably of:

- Cement according to EN 196 and ASTM C 191

- Gypsum according to EN 13279 and ASTM C 472

- Mortar according to EN 480 and ASTM C 807

- The compact stand-alone solution for the automatic determination of the setting behaviour in conformity with standards. No external temperature control necessary.

- Robust low-maintenance precipitation with automatic cleaning of the penetrating needle.

- Turbo mode for fast setting building materials.

- Easy data export via USB stick.

- Simple conversion to other product standards e.g. cement, mortar in less than a minute.

-

Automatic mixing of cement, mortar, gypsum and other materials including automated sand and water addition. Standard-compliant operation according to EN 196-1, EN 196-3, EN 480-1, ASTM C305, ASTM C359, ASTM C451, ISO 679 and other standards. Key benefits for the user:

- High standard of work safety due to access protection, splash guard and interlocks*

- Simple operation

- Intuitive operation

- Plug & Play: immediately ready for use

- Downward compatible tools: continue to use your existing stirrers and keys of the ToniMIX type

- Standard-compliant mixing processes according to EN, ISO, ASTM** including water dosing

-

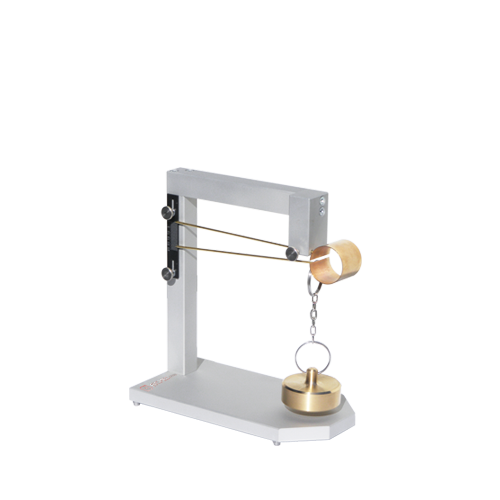

Device for the standard-compliant testing of the expansion of Le Chatelier moulds without permanent deformation (resilience) according to EN 196-3. The device consists of a solid base plate onto that a stand is mounted. The stand has a clamping device to clamp the Le Chatelier moulds and has an adjustable scale to measure the expansion of the mould. A weight and a key ring chain with a total mass of 300 g are part of the delivery. Key benefits for the user: ✓ Adjustable scale for the adaption to the indicator needles ✓ Easy, user-friendly handling ✓ Solid design made of aluminum

-

Application For the determination of the volume consistency of cement in accordance with DIN EN 196-3. Design The ring consists of a fexible sheet body, made of copper-zinc alloy, with two measuring needles. Working Principle The slightly oiled ring is placed onto a glass plate, manually filled with standard compliant cement paste and covered with a second glass plate on which a weight of approx. 50 grams is placed. Then the ring is exposed to a standard climate. After the setting of the cement paste the spread of the ring is measured at the end of the measuring needles.

-

Load frame with large testing area dimensions for standard-compliant compressive strength tests on building material specimens of all kind, e.g. concrete-, brick- and natural stone specimens. This load frame is made for extremely challenging test requirements in the quality control, the development and the research.

- Accuracy: Quality Class 1 / DIN 51220 / EN ISO 7500-1

- Sizes: 5000 kN / 6000 kN / 8000 kN / 10000 kN

-

Performance unit for the generation of a defined ambient temperature for the cement calorimeters of the ToniCAL series. Key benefits for the user: ✓ Storage space for consumables ✓ Integrable into ToniSYSTEMLABORATORY ✓ Precise temperature control, unaffected by the room temperature ✓ Subsequent integration of the available cement calorimeters of the series ToniCAL ✓ Installation space for monitor, mouse and keyboard ✓ Difference in temperature between measuring cell and ambience ✓ Storage space for the integration of a PC inside the unit ✓ Guarantee of an ambient temperature for the realization of the isotherm heat flow calorimetry at a temperature of 20°C respectively a preselected temperature ✓ Functional and user-friendly assembly of the control devices

-

Compact, fully automatic test plant for standard-compliant flexural strength tests on cement and other binding materials, preferably on prisms 40 x 40 x 160 mm in accordance with EN 196 and ISO 679.

- Accuracy: Quality Class 1 / EN ISO 7500-1 / DIN 51220

- Sizes: 10 kN / 20 kN / 50 kN

-

Load frame for efficient, standard-compliant flexural strength tests on mortar prisms, preferably on prisms 40x40x160 mm in accordance with EN 196 and ISO 679.

- Accuracy: Quality Class 1 / EN ISO 7500-1 / DIN 51220

- Sizes: 10 kN / 20 kN / 50 kN

-

The universal interface software ToniLINK enables the bi- or unidirectional data transmission between a PC and the ToniTROL respectively the ToniPERM.

Key benefits for the user:

✓ Installation and setup by the user possible ✓ Testing orders can be sent to the ToniTROL ✓ Linkage with laboratory information systems (LIMS) ✓ Easy operation by onetime definition of the results to be stored and their order ✓ Calculation of the average value and the standard deviation ✓ Storage in ASCII-format with selectable separator