- Our standard device (EN 196-6; ASTM C 204) for laboratory use in conformity with the standards

- Simple operation with reproducible results

- Intuitive operation with touch screen

- Automatic volume correction

- Robust, low-maintenance design*

- Easy data export via LAN interface** or USB stick

-

The air permeability tester ToniPERM is designed for the determination of the specific surface of powders, especially suitable for the permanent control of manufacturing characteristics in the daily laboratory work according to EN 196 and ASTM C 204. Key benefits for the user:

-

Application Automatic, computer-controlled Vicat needle instrument providing eight measuring stations for the determination of the setting characteristics of binding materials, preferably of: Key benefits for the user:

- Cost-effective solution for the automatic determination of the setting behaviour of cement in air-conditioned laboratories in conformity with standards by omission of the internal temperature control unit

- Robust low-maintenance execution with automatic cleaning of the penetrating needle

- Fast tesing mode for rapid setting building materials

- Easy data export via USB stick

-

The analyzer TonLIME is designed to determine the content of free, uncombined lime in cement and cement clinker. The operating principle is based on the measurement of the electric conductivity in a solution consisting of cement and hot glycol in comparison with a stored calibration curve. Key factors for the user:

- Measurement result in less than 10 minutes, very short preparation time for the user

- no operator intervention required during the test procedure

- Connection to a PC for parameterization and evaluation of the results via the RS 232 and RS 485 interfaces is also possible

- integrated database with all necessary test parameters and intelligent menu navigation

-

The Water Bath ToniCHAT allows the standard-compliant, controlled boiling of binding agent samples (i.e. Le Chatelier moulds) for the determination of the volume stability or rate of risk regarding a subsequent extension of the binding agent (cement) caused by hydration. The ToniCHAT corresponds exactly to the requirements of the standard EN 196-3 and performs an autonomous and controlled test cycle. Key benefits for the user: ✓ Permanent indication of target / actual temperature ✓ Temperature control with an exactitude of 0.1°C ✓ Capacity for up to 16 Le Chatelier Rings ✓ Test execution optionally under water or steam ✓ Fully automatic test cycles according to defined parameters ✓ Controlled test procedure for accurate reproducible test results ✓ Integrated drain hose for an easy and fast water change ✓ Heating up from 20°C to 100°C within 30±5 minutes ✓ Stabilization of boiling temperature for three hours

-

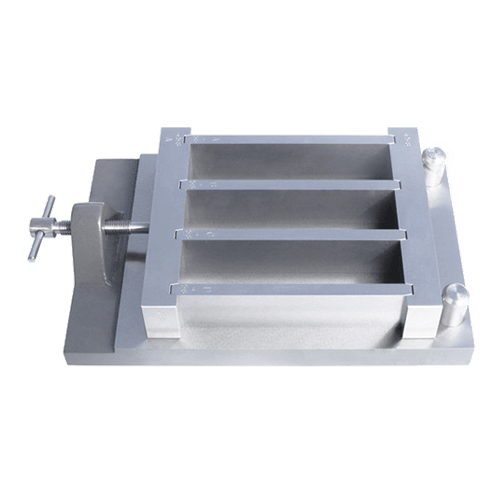

Application Preparation of prism shaped samples, 40x40x160 mm made of mortar, especially cement mortar in accordance with the standards EN 196 1, ISO 679, DIN EN 12808 4, EN 1015 11 and ASTM C 348. Advantages

- The bars and end pieces are individually marked to ensure a perfect fit

- The design of the base plate and surface grinding avoids deformation of the mould in the long term

- The special steel used ensures the prescribed dimensional stability in the long term when using brass rulers

- The mould can be supplied with or without bores for the shrinkage test

-

Test plant in compact design for efficient, standard-compliant compressive strength tests on cement and other binding materials, preferably on:

- delivery as a ready-to-use, space-saving compact unit: "Set up, connect, test".

- very easy programming and operation

- possibility to connect to Laboratory Information and Management Systems (LIMS)

- future-proof through retrofittable software options

- US-units selectable (lbs, psi, inch,…)

-

Fully automatic test plant in compact design for standard-compliant compressive strength tests on building materials, preferably for efficient routine tests and quality control on:

- Concrete cylinders 4 inch / 6 inch according to ASTM C 39

- Concrete cubes 100 mm / 150 mm edge length according to EN 12390-3

- Delivery as a ready-to-use, space-saving compact unit: "Set up, connect, test".

- The high-precision manufactured spherical calotte is form-fit and backlash-free, finely tuned to the spherical shell and enables very precise force transmission

- Connection possibility for scales, caliper, barcode reader and printer for automatic printout of raw data

- Servo-hydraulic control in a closed control loop

- Operation and evaluation via PC using testXpert III testing software

- US-units selectable (lbs, psi, inch,…)

-

Fully automatic test plant in compact design for standard-compliant compressive strength tests on building materials, preferably for efficient routine tests and quality control on:

- Cylinders 150 x 300 mm or 160 x 320 mm according to EN 12390-3

- Cylinders 150 x 300 mm or 160 x 320 mm according to EN 12390-4 (strain cylinder test)

- Cubes with 100 mm, 150 mm or 200 mm edge length according to EN 12390-3

- Cubes with 100 mm, 150 mm or 200 mm edge length according to EN 12390-4 (strain cylinder test)

- Accuracy: Quality Class 1 / DIN 51220 / EN ISO 7500-1

- Sizes: 2000 kN / 3000 kN / 4000 kN

-

Load frame in compact design for the standard-compliant compressive strength tests on building materials, preferably for efficient routine tests and quality control on:

- Concrete cylinders 150 x 300 mm or 160 x 320 mm according to EN 12390-3

- Concrete cubes with 100 mm, 150 mm or 200 mm edge length according to EN 12390-3

- Accuracy: Quality Class 1 / DIN 51220 / EN ISO 7500-1 / EN 12390-4

- Sizes: 2000 kN / 3000 kN / 4000 kN

-

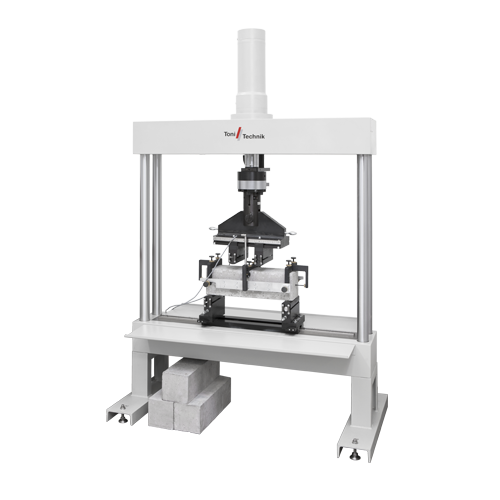

Combined test plant for the standard-compliant testing of the compressive and flexural strength of cement and other binding materials, preferably for efficient routine tests of:

- Prisms 40 x 40 x 160 mm accord. to EN 196 / ISO 679

- Cubes 50 mm (2 inch) according to ASTM C109

- Cubes 70.7 mm according to BS 1881

Key benefits for the user:

- connection possibility for a third load frame, e.g. 3000 kN compression test frame for concrete testing

- possibility of machine control and test evaluation via a PC using testXpert software

- future-proof through retrofittable software modules

- possibility to connect to Laboratory Information and Management Systems (LIMS)

-

Load frame for standard-compliant testing of the flexural strength of gypsum plates, plates made of fiber materials, concrete bars, concrete stone products (curb stones, paving stones), building material specimens and whole components, e.g. according to EN 12390-5. Accuracy: Quality Class 1 / EN ISO 7500-1 / DIN 51220 Sizes: 10 kN / 20 kN / 100 kN / 200 kN / 300 kN