Description

Key benefits for the user:

- Easy programming and user-friendly operation

- Designed as space-saving compact unit

- Young´s modulus measurement possible

- Microprocessor and servo-hydraulic control (closed loop)

- Control by PC with software testXpert

- Future-proof by various software extensions

- High torsional stiffness (max. 1 mm expansion at full load)

- Result evaluation by PC with software testXpert

For the ToniPACT II are various pressure plates, a large range of accessories and optional extensions available.

Design / Operating Principle

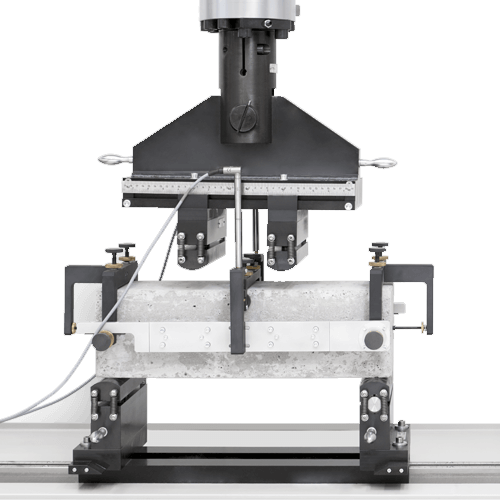

Torsion-resistant, four-column load frame with backlash-free braced columns in space-saving compact design.

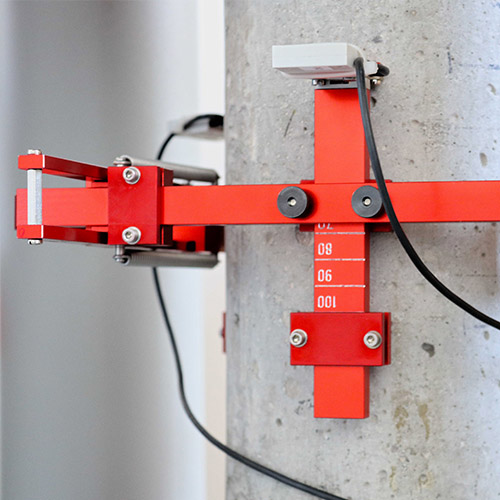

Bottom-mounted plunger drive with hardened piston, equipped with protective cover, stroke indicator and limit switch for stroke limitation. Piston and cylinder are finely ground.

Pressure plates hardened and ground. Upper pressure plate tiltable by 3° by means of a ball seat. Lower pressure plate provided with crosshair and centering ring.

All hydraulic components, such as pressure oil unit and servo valve, are installed in the laterally arranged control column. Pressure oil unit with radial piston pump; flow rate 1.4 l/min up to max. 450 bar. The digital measuring and control system ToniTROL II is installed on the control column.

The tests are prepared, carried out, monitored and evaluated via the ToniTROL II or via a PC using the intuitive testXpert III testing software. The control is effected via a servo valve in a closed loop system. The test load is measured with a high-precision oil pressure transducer.