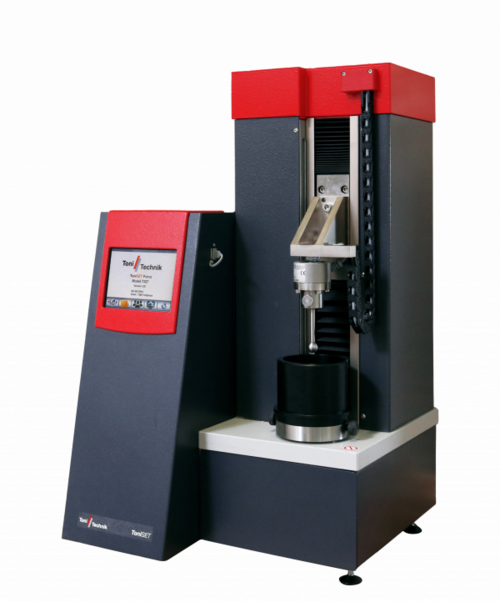

Computer controlled isothermal heat flow calorimeter for the continuous determination of the total evolved heat of hydration of binding materials, preferably of cement according to ASTM C1702.

With online computer operation the instrument allows to directly determine the heat development rate (J/g) in dependence of the elapsed time. Object is the use for rational Quality Control as alternative methods for ASTM C186 and DIN EN 196-8.

Key benefits for the user:

✓ Rigid, durable measuring instrument for industrial and laboratory tasks

✓ Self-calibration function by operator

✓ Very high detection sensitivity by three switchable measuring ranges for different types of binding materials

✓ Test method with great informational value and with very good reproducibility

✓ Detection of the initial peak

✓ Difference in temperature between measuring cell and ambience

✓ Extension for testing additives by adapting an after-injection module with homogenization function

✓ Evaluation of the results via computer with numerical and/or graphical output