With the company AGC INTERPANE Safety Glass we have designed a testing machine according to your needs already in 2003 and derived it very easily from our ToniNORM series.

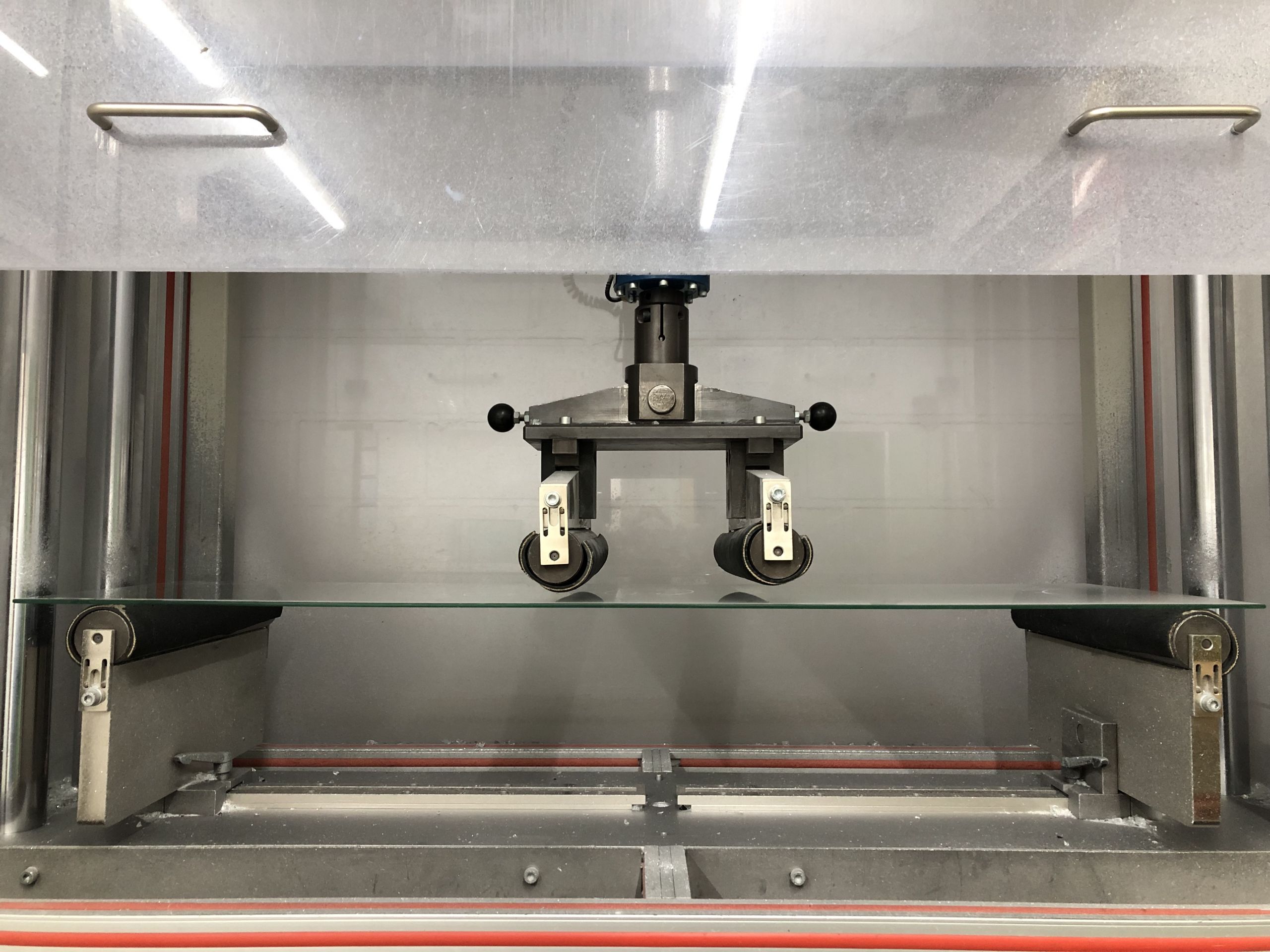

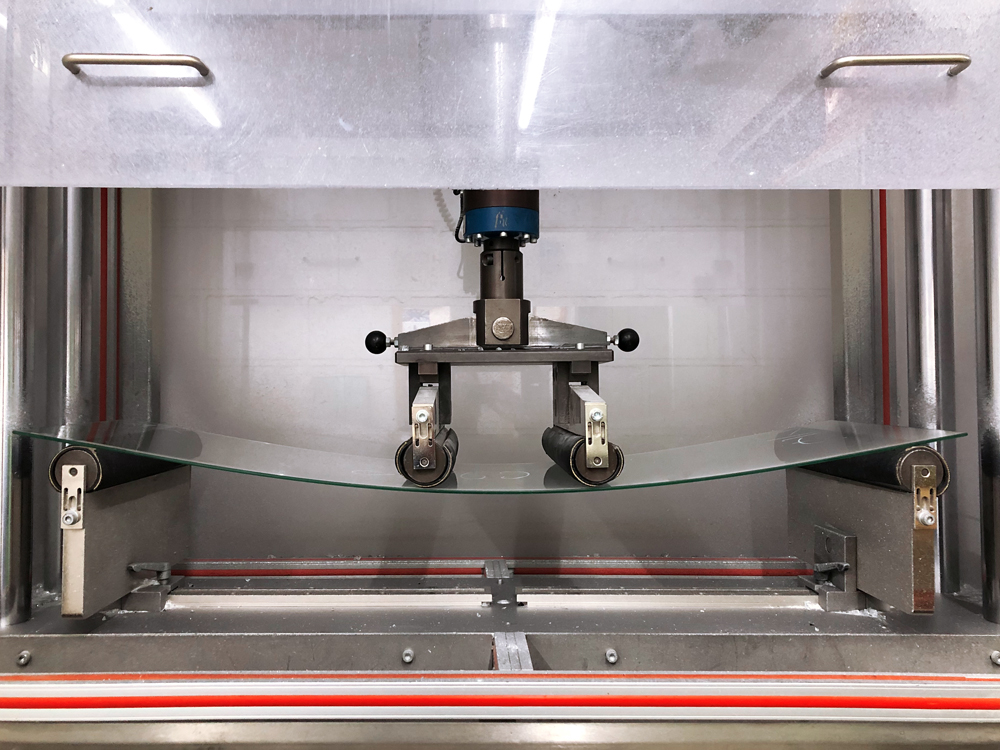

The bending strength itself is tested according to DIN EN 1288-1 Fundamentals or DIN EN 1288-3 Determination of the bending tensile strength of glass – with two-sided support.

This is required by DIN EN 12150-1 ” Thermally toughened soda-lime single-pane safety glass” and DIN EN 14179 “Heat-strengthened thermally toughened soda-lime single-pane safety glass”.

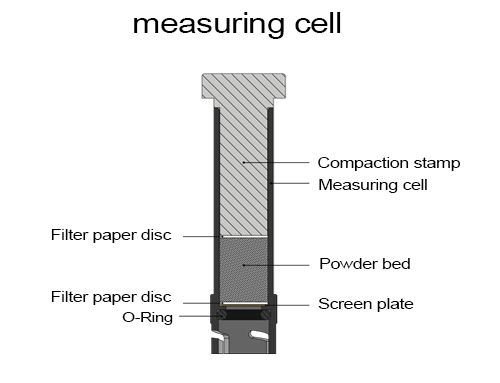

In addition, the company AGC INTERPANE still test ship glass in a non-destructive stamp test according to the standard DIN ISO 614 “Ships and marine technology – Panes of toughened safety glass for rectangular and circular ship windows – Stamp test for non-destructive testing of strength”.

An important requirement of the required 50 kN bending testing machine was to optimize the glass splinter protection as well as the disposal of the glass splinter residues in a truly “application-oriented” manner. For this purpose, the base frame of the ToniNORM load frame was raised and waste chutes running all around were designed under a solid test space protection enclosure.

A commercially available disposal container, moved with a lift truck, takes up the glass residues without any problems during “daily testing” to this day.

The today 20zig year old Toni Technik testing machine, with only 50 kN testing force, was already competitively priced at the time of delivery to AGC INTERPANE and is still today a fine example of a servo-hydraulic application solution even with quite small forces!

The following advantages of this concept are also obvious:

- Glass insensitive drive technology due to hydraulic cylinder on top.

- Extremely stiff load frame, thus very accurate deflection measurement via piston travel.

- Robust hydraulic Toni Technik control technology, proven 1000 times over

- Reliable maintenance and calibration at reasonable cost.