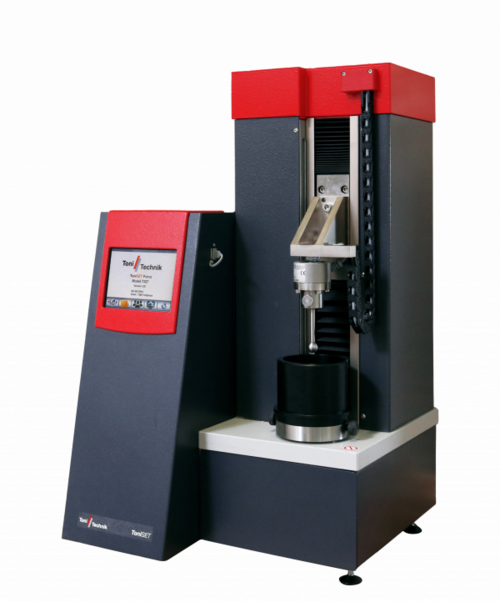

Description

Working Principle

A defined amount of the pulverized sample is filled into a thin walled measuring vessel (usual test glass) and placed in one of the six measuring cells within the calorimeter vessel. A further vessel (re-usable injection syringe) with the fluid portion is integrated into each sample vessel. Simultaneously or timely independent all measuring cells can be filled with the same or different materials. A totally tempered inert sample with the same filling height is allocated to each measuring chamber.

After the thermal balance is reached in the measuring cell(s) the both reaction partners (normally binding materials and distilled water) will be mixed under pressure within a few seconds.

Using an optional later injection module, designed for two fluid vessels, a further reaction partner (additives as BV, FM or others) can be dosed later and mixed with the ductile sample by means of a manually operated agitator rod. Directly with the mixing of the reaction partners starts the continuous recording of the thermo-voltage [mV] as measure for the produced quantity of heat.

All measured values, graphics and test parameters will be stored in a database and can be exported.

The complete data capturing and evaluation for the test is realized by the software ToniDCA, which is installable on a common PC system (limited IBM) from Pentium II with the operation systems Windows 95/98/2000/NT/XP