-

Application For the determination of the volume consistency of cement in accordance with DIN EN 196-3. Design The ring consists of a fexible sheet body, made of copper-zinc alloy, with two measuring needles. Working Principle The slightly oiled ring is placed onto a glass plate, manually filled with standard compliant cement paste and covered with a second glass plate on which a weight of approx. 50 grams is placed. Then the ring is exposed to a standard climate. After the setting of the cement paste the spread of the ring is measured at the end of the measuring needles.

-

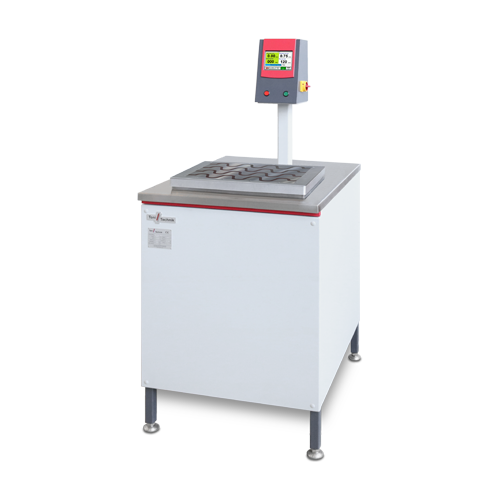

The Water Bath ToniCHAT allows the standard-compliant, controlled boiling of binding agent samples (i.e. Le Chatelier moulds) for the determination of the volume stability or rate of risk regarding a subsequent extension of the binding agent (cement) caused by hydration. The ToniCHAT corresponds exactly to the requirements of the standard EN 196-3 and performs an autonomous and controlled test cycle. Key benefits for the user: ✓ Permanent indication of target / actual temperature ✓ Temperature control with an exactitude of 0.1°C ✓ Capacity for up to 16 Le Chatelier Rings ✓ Test execution optionally under water or steam ✓ Fully automatic test cycles according to defined parameters ✓ Controlled test procedure for accurate reproducible test results ✓ Integrated drain hose for an easy and fast water change ✓ Heating up from 20°C to 100°C within 30±5 minutes ✓ Stabilization of boiling temperature for three hours

-

Manual air permeability tester according to Blaine for the determination of the specific surface (grinding fineness / Blaine value) of cement and other powdered materials in accordance with EN 196 and ASTM C 204. Design Lacquered steel sheet stand with mounted U-tube manometer. The manometer is equipped with a conical seat for the measuring cell and level marks for the manometer fluid. The measuring cell is made of stainless steel and fits exactly to the conical seat of the U-tube manometer. Behind the manometer a mirror is mounted to avoid reading errors. To record the ambient temperature a thermometer is installed on the instrument.

-

Automatic mixing of cement, mortar, gypsum and other materials including automated sand and water addition. Standard-compliant operation according to EN 196-1, EN 196-3, EN 480-1, ASTM C305, ASTM C359, ASTM C451, ISO 679 and other standards. Key benefits for the user:

- High standard of work safety due to access protection, splash guard and interlocks*

- Simple operation

- Intuitive operation

- Plug & Play: immediately ready for use

- Downward compatible tools: continue to use your existing stirrers and keys of the ToniMIX type

- Standard-compliant mixing processes according to EN, ISO, ASTM** including water dosing

-

Application Mortar mixer for the standard-compliant preparation of cement mortar and cement paste according to EN 196, ISO 679, DIN 1164, ASTM C 305, Ö-Norm B 3310 and further standards. Key benefits for the user:

- robust, durable housing

- wear-resistant, precise stirring tool

- possibility of adding granular and liquid aggregates during the mixing procedure

- integrated connection for dust exhaust

-

Standard-compliant operation according to EN 196-1, EN 196-3, EN 480-1, ASTM C 305, ASTM C 359, ASTM C 451, ISO 679 and according to own specifications. Automatic mixing of cement, mortar, gypsum and other materials including automated feed of sand and water Key benefits for the user:

- High standard of work safety, user-friendliness and conformity to norms as with ToniMIX Standard.

- Convenient programming of own customer-specific mixing processes, also according to local standards

- Infinite adjustable of stirring rate and water dosing for individual standards and building materials, e.g. lightweight construction materials

- Equipped with an automatic sand feeding system

- LED illuminated, visible mixing chamber

- Connection for a dust extraction device included as standard

-

Standard-compliant operation according to EN 196-1, EN 196-3, EN 480-1, ASTM C 305, ASTM C 359, ASTM C 451, ISO 679 and according to own specifications. Automatic mixing of cement, mortar, gypsum and other materials including automated feed of sand and water, as well as torque measurement for the production of a defined viscosity. Advantages

- Our best Mixer with all features of ToniMIX Standard and ToniMIX Expert

- Determination and recording of viscosity behaviour of the mixture by means of torque measurement

- Equipped with an automatic sand feeding system

- Simply optimization of the mortar rheology by automatic water dosing to achieve a target viscosity value

- LED illuminated, visible mixing chamber

- Connection for a dust extraction device integrated

-

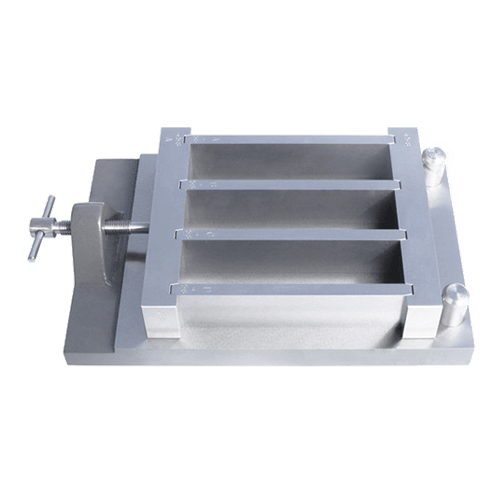

Application Preparation of prism shaped samples, 40x40x160 mm made of mortar, especially cement mortar in accordance with the standards EN 196 1, ISO 679, DIN EN 12808 4, EN 1015 11 and ASTM C 348. Advantages

- The bars and end pieces are individually marked to ensure a perfect fit

- The design of the base plate and surface grinding avoids deformation of the mould in the long term

- The special steel used ensures the prescribed dimensional stability in the long term when using brass rulers

- The mould can be supplied with or without bores for the shrinkage test

-

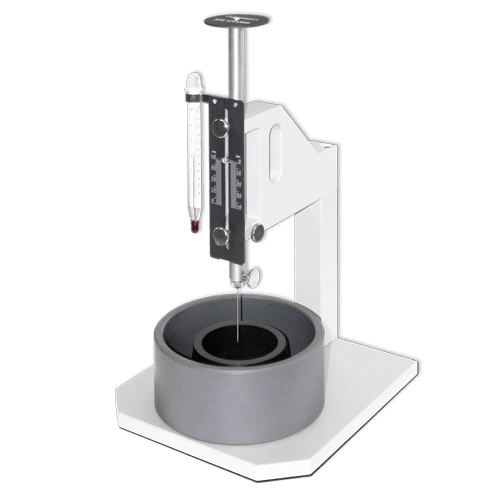

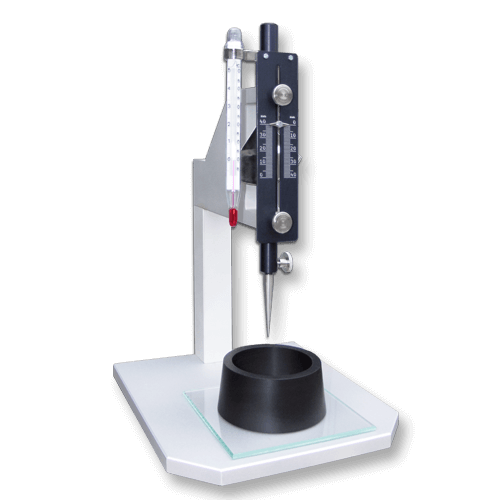

Application Manual Vicat needle device with a measuring point for determining the solidification behavior of binders, in particular:

- Cement according to EN 196, ASTM C 187 and ASTM C 191

- Mortar according to EN 480 and ASTM C 807

-

Application Determination of the initiation of stiffening of gypsum in accordance with DIN EN 13279 Part 2 and ASTM C191. Analysis of the setting behavior of dental gypsum in accordance with DIN EN 26873.

- Gips nach EN 13279 und ASTM C 472

- Dentalgips nach EN 26873

-

Application For the storage of specimens in tempered water. Advantages ✓ Compatible with the ToniSYSTEMLABORATORY ✓ Easy operation and handling ✓ High storage capacity by storage in six respectively seven levels ✓ Integrated thermostat with digital display for the actual value and the set value

-

Performance unit for the standard-compliant compaction of unshaped refractory products like dense, thermal insulating refractory concrete and other building materials in accordance with EN ISO 1927-5. The ToniVIB magnetic features a magnetic clamping plate for clamping of the moulds. Key benefits for the user:

- Closed-loop operation in accordance with the standards, for automatic adjustment of the selected amplitude, independent of the weight of the mould and the mass to be compacted

- Comfortable magnetic clamping of mould and mould attachment

- Parameterization via touch screen, last selected settings are saved

- Comfortable single button operation START / STOP