Non-metallic ceramic materials and composites whose softening points are above 1,500 ° C are defined as refractory material.

Refractory materials, which are separated into shaped (e.g. stones, blocks, slabs) and unshaped (e.g. cement, mortar, concrete) materials, are mainly used in high temperature industrial processes.

To determine the requested strength Toni Technik provides intelligent test solutions:

- Determination of compressive strength in accordance with DIN EN 993-5 and DIN EN ISO 8895

- Determination of flexural strength according to DIN EN 993-6, DIN EN 843-1, ASTM C1161, DIN EN 658-3 and DIN EN 843-2

- Determination of modulus of elasticity according to EN 843-2

-

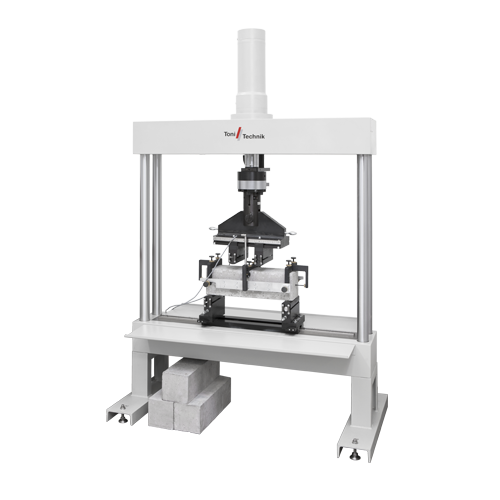

Multi-purpose load frame for standard-compliant flexural strength tests on plates, bars, standard stones, roofing tiles and further building materials and components. Accuracy: Quality Class 1 / EN ISO 7500-1 / DIN 51220 Sizes: 10 kN / 20 kN / 50 kN

-

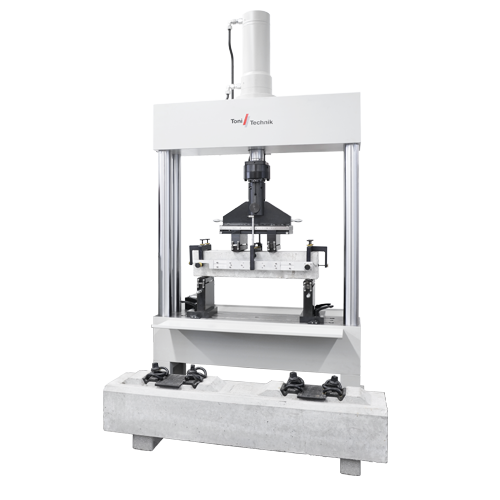

Load frame for standard-compliant testing of the flexural strength of gypsum plates, plates made of fiber materials, concrete bars, concrete stone products (curb stones, paving stones), building material specimens and whole components, e.g. according to EN 12390-5. Accuracy: Quality Class 1 / EN ISO 7500-1 / DIN 51220 Sizes: 10 kN / 20 kN / 100 kN / 200 kN / 300 kN

-

Load frame for standard-compliant flexural strength tests on concrete bars, concrete stone products, building material specimens and components. Accuracy: Quality Class 1 / EN ISO 7500-1 / DIN 51220 Sizes: 200 kN / 300 kN

-

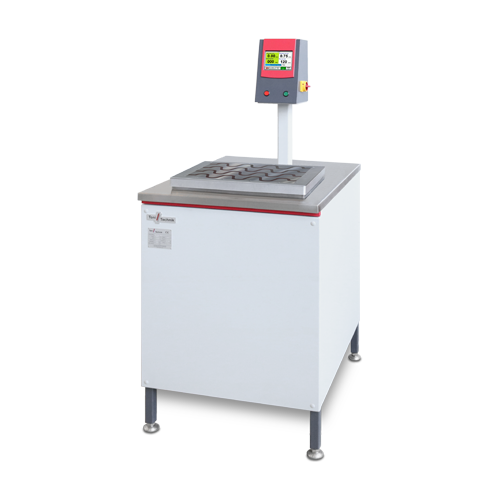

Performance unit for the standard-compliant compaction of unshaped refractory products like dense, thermal insulating refractory concrete and other building materials in accordance with EN ISO 1927-5. The ToniVIB magnetic features a magnetic clamping plate for clamping of the moulds. Key benefits for the user:

- Closed-loop operation in accordance with the standards, for automatic adjustment of the selected amplitude, independent of the weight of the mould and the mass to be compacted

- Comfortable magnetic clamping of mould and mould attachment

- Parameterization via touch screen, last selected settings are saved

- Comfortable single button operation START / STOP

-

The plasticity tester is designed for the determination of the workability of ceramic materials. The plasticity value according to Pfefferkorn is determined by measuring the plasticity of a specimen between a fixed lower bearing plate and a free falling upper brass plate. Advantages ✓ Reliable evaluation of characteristic values ✓ Simple operation

-

Operating Principle

The viscosity tester type Lehmann is designed to determine the viscosity of glazing and clay slips. The time is measured that a defined amount of test material needs to run through a nozzle with a specific cross section into a volumetric flask. Subsequently the viscosity value can be determined comparing the time with such a slip of known consistency needs.

Advantages

✓ High repeatability ✓ High accuracy ✓ Simple technique and handling ✓ Simple and quick measuring procedure (advantageous for test series and quality control)