Maintenance & Calibration

ToniSERVICE calibrates your material testing machines and systems in accordance with various international standards including EN and ASTM.

The maintenance and calibration service is accredited as DAkkS calibration laboratory. It is therefore authorized to calibrate testing machines and systems at site according to ISO 17025 and to issue calibration certificates, which are recognized worldwide.

Your key advantages:

- During the visit, our calibration service technicians can maintain, adjust and calibrate the testing machines and systems of Toni Technik GmbH and also other brands. This saves time and costs.

- With a maintenance contract, which is individually tailored to your requirements at a fixed price, you secure a flawless function and long-term value preservation of your test systems.

- Maintenance contracts have a number of advantages over individual orders.

Commissioning

Toni Technik delivers all standard products on very short notice. The commissioning can be done upon delivery or at any desired time. The service includes unpacking, installation, software setup and training of the future users directly on-site.

Our trained and experienced service engineers technicians take your testing system in operation and instruct your employees individually in the commissioning, the operation and the maintenance of the product.

To meet the different requirements of our customers, we offer a variety of different service packages, ranging from a purely basic installation up to a complete package with comprehensive user training on-site.

- unpacking, setting up, connecting

- software setup

- instruction / training directly on-site

- adaptation of the scope of services to customer´s requirements

Training

Studies have shown that more than half of the problems with technical systems are not caused by the technology itself, but rather by the incorrect operation. Individual trainings of the user avoid possible problems and lead to a reduction in service costs.

In our seminars, both the theoretical foundations and the practical handling of our testing machines and instruments will be trained. The evaluation and interpretation of test data and results are also a part of the training.

The training can be performed at your premises either at Toni Technik in Berlin or in the branches of our representatives.

Repair

If nevertheless a machine should fail, ToniService helps immediately.

Spare parts are quickly on site and a large number of service engineers with specific tooling sets ensure worldwide service coverage.

Due to the fast response times provided for in our maintenance agreements, you get the service you need on site within a short time, ensuring a minimum downtime.

Simple repairs to parts are best carried out in our facilities in Berlin. Just send us the defective part and we will repair and return it to within a short time. This saves the travelling expenses of the service engineer.

Spare Parts & Consumables

In most cases, we can guarantee the availability of our spare parts for a period of more than 10 years after delivery of your machine.

In fact, we also supply spare parts for many of our testing machines manufactured in the 60s and 70s, which still run properly after half a century.

All our service technicians have fully equipped service vehicles and carry common spare and wear parts with them, together with the necessary special tools.

Modernization / Upgrades

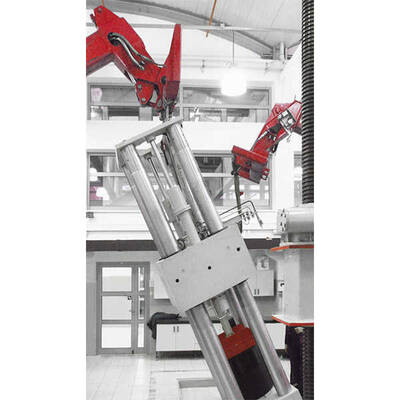

We modernize testing machines of all manufacturers!

The choice between a new purchase and modernization depends primarily on the value and technical condition of the existing machine components. Since in addition to the load frame also other components can be further used, as for instance load cells or sample holders the cost of modernization are usually less than for a new machine or plant.

After a successful modernization you will get detailed instruction about the new technology.

All modernization have attractive prices and can be carried out on short notice.

Substance conservation while increasing the intelligence – this is the purpose of modernization of old compression- and bending test machines with ToniTROL. By using a flexible modernization package with proven hydraulic-, electronic- and software components out of the current testing machines series ToniNORM, the existing building material machines can be build up to intelligent, multifunctional applicable and upgradeable testing systems, which meet the current testing- and safety standards.

Pre-owned Machines & Instruments

Is a once-read book worthless?

Toni Technik offers pre-owned testing machines and instruments in audited Toni Technik quality with warranty.

Testing machines are extremely robust and offer a long service life. If they are equipped with used or new accessories by Toni Technik, these machines will meet all current requirements and are still of high quality.

Every used testing machine or instrument sold by Toni Technik has been subjected to a rigorous process of checking and testing before delivery. Older second-hand testing machines have been modernized in line with the state of the art and allow therefore the use of features from the current Toni Technik product range, such as for instance the machine control and test evaluation via a PC, using the leading testing software testXpert®.

That’s why we are able to give our customers a 12-month guarantee also on these products.